Stirrers : Turbines

The turbines for stirrers have straight, curved or inclined blades. The flow is sucked axially and discharged radially. They generate shear and turbulence.

Turbines are used in various sectors: chemistry and petrochemistry, pharmaceuticals and biotechnology, food processing and cosmetics.

Their characteristics make them suitable products for these applications, with variations according to the models: thermal transfer, suspension, miscible liquid mixture, suspension, suspension retention, homogenization, emulsion, dilution, deltination, gas/liquid dispersion, solid/liquid dispersion, liquid/liquid dispersion, gas absorption, dissolution…

Turbines are used in various sectors: chemistry and petrochemistry, pharmaceuticals and biotechnology, food processing and cosmetics.

Their characteristics make them suitable products for these applications, with variations according to the models: thermal transfer, suspension, miscible liquid mixture, suspension, suspension retention, homogenization, emulsion, dilution, deltination, gas/liquid dispersion, solid/liquid dispersion, liquid/liquid dispersion, gas absorption, dissolution…

AGITEC® offers several types of turbines

The AGITEC® range of impellers is suitable for a wide range of applications where different processes take place. A mechanical agitator equipped with an impeller has a powerful system with a more or less high centrifugal effect depending on the type of impeller used.

The development of our standard impellers meets the specific needs of industrial stirring. They are used from the moment the container is filled until the mixed products are completely emptied, whatever their viscosity.

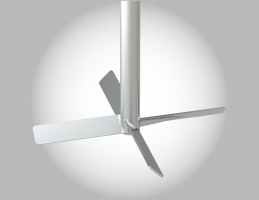

3PC, 6PC

The curved blade turbine is mainly used at the bottom of the tank for its high centrifugal effect. This avoids any risk of settling solid products at the bottom of the tank.TA4, TA3, TA2

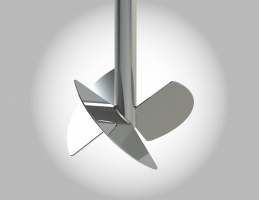

This turbine with straight blades inclined at 45° is a hybrid mobile between the propeller and the conventional turbine. It allows a radial centrifugal effect combined with an axial vertical effect.TF2, TF3

The flat TF turbine with straight blades is always at or near the bottom of the tank. Thanks to it, the mixing effect can be maintained until the container is completely emptied (or during filling). It must be associated with a pumping mobile.DISPERSION

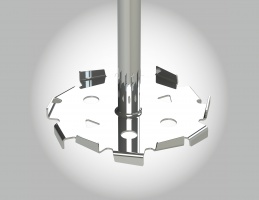

The flat dispersion turbine with toothed disc generates, thanks to its high peripheral speed, a vacuum that centrifuges the liquids and solids sucked in and propels them through its teeth.RUSHTON

The Rushton vertical blade disc turbine is mainly used for gas/liquid dispersion by centrifugal effect. This dispersion promotes gas/liquid exchange.DISGAZ

The Disgaz turbine with serrated blades allows to obtain gaseous dispersion effects as the Rushton turbine does, by significantly reducing the power consumed.This latest generation turbine is suitable for new installations, or turbines to be replaced.

AUTO-ASPIRANTE

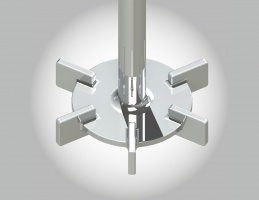

The self-priming turbine with double discs and vertical plates disperses the gas contained in a liquid. It is used because of its high centrifugal effect.ROTOR/STATOR

The Rotor/Stator mobile consists of a turbine with 4 straight blades (Rotor) and a cylinder with vertical openings (Stator). This torque makes it possible to produce emulsion type mixtures.OREILLES D'ÉLÉPHANT

The elephant ear turbine with 45° inclined blades is used for applications requiring high hydraulic lift without waiting for a significant mixing effect.News

AGITEC takes care of your energy costs

Development of a new Low Energy Consumption range.