Applications > Heat transfer

What is heat transfer?

Heat transfer, more commonly just called heat, is an exchange of thermal energy between two bodies at different temperatures, in order to obtain molecular change (evolution) and thermal equilibrium between them. It corresponds to a chaotic microscopic energy transmission. The three fundamental heat transfer methods are conduction, convection and radiation.

A fundamental concept of thermodynamics, heat transfer refers to a thermal exchange between two bodies, whether liquids, solids or gases, in order to obtain a thermal equilibrium between them through their molecular evolution.

It is therefore a process of internal energy exchange.

Heat transfers are carried out by conduction, convection or radiation and allow the heating or cooling of a product mixture in a tank. The level of heat exchange depends on different parameters such as the stirring speed or the structure of the mobiles used for the agitator equipment.

Heat transfer can only take place from the hot source to the cold source and is irreversible.

Thermal conduction is adapted to fluids and solids, the transfer of the kinetic energy of the molecules being done without matter exchange, contrary to convection where the exchange of matter is carried out between leaks, liquids and gases by a movement of the particles.

In the industrial fields of agitation, thermal exchanges are mainly used for dissolutions and homogenizations, or to create a chemical reaction and/or a specific physico-chemical transformation.

What industrial applications use thermal transfer?

The chemical, pharmaceutical labotorie, food or cosmetics industries produce, use or transform complex fluids on a daily basis via the heat transfer process for their heating or cooling. More generally, these are fluids with high or very high viscosity, but also with intermediate viscosity for products with simple behaviour or containing solid particles.

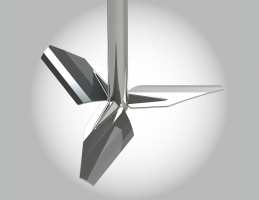

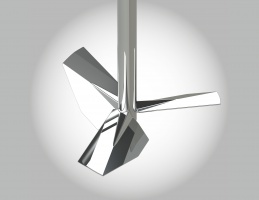

Heat transfer operations are carried out in tanks with stirrers equipped with mobiles such as turbines, propellers or anchors, which often prove to be the most suitable for this process depending on the characteristics of the fluids for which heat transfer is required.

Which stirrer to use for thermal transfer?

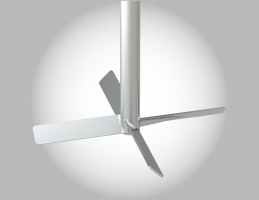

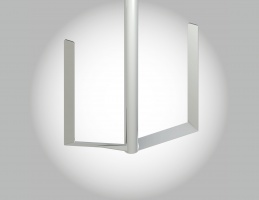

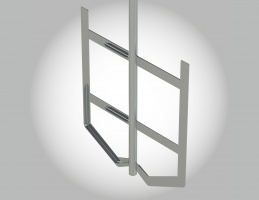

AGITEC® offers a range of anchors that can be adapted to the size of the tanks and their lids. This mobile agitator is perfectly suited to processes requiring the mixing of viscous products inside a container (batch mixing).

For products with intermediate viscosity, a stirrer with a flat inclined anchor is a system that creates a tangential and axial flow perfectly adapted to heat transfer. With a flat anchor, the agitator will generate a predominantly tangential flow with a limited speed of rotation.

The tubular anchor is particularly designed for complex mixtures with high viscosity where helical or scraper anchors are ideal for homogenising mixtures of high viscosity products.