News

Mixing stirring device for iBC tanks: the new range from agitec

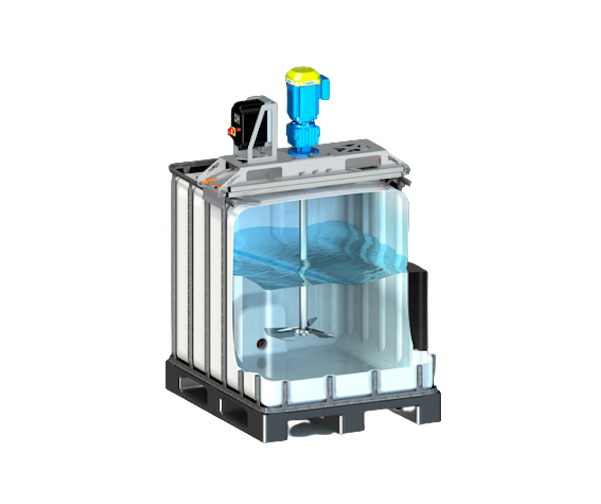

AGITEC® has designed a range of stirrers for mixing liquids packaged in IBV (Intermediate Bulk Container) containers. With a wide range of options available, the AG-IBC range of mixers is perfectly suited to the needs of slurrying applications, mixing miscible liquids, keeping a liquid/solid mixture in suspension and liquid/liquid homogenisation. Designed with high-performance equipment (asynchronous geared motor, variable frequency drive, folding propeller, etc.), the stirrers for IBC tanks are easy to use in industrial sectors such as chemicals/petrochemicals, food processing, water treatment and cosmetics.

THE ADVANTAGES OF AN IBC CONTAINER FOR INDUSTRIAL APPLICATIONS

IBCs (Intermediate Bulk Containers) are widely used in industry for storing and transporting all types of liquids. They are also used in a wide range of applications in sectors as varied as food manufacturing, chemical product design and cosmetics. IBCs are also extremely useful in the water treatment process.

Their large capacity means they can handle 1,000 litres of liquids ranging from water to medium-viscosity products (8,000 centipoises). Their mobility is also an advantage, as the mixture obtained after agitation can be transported without being poured into another container. Their design, based on specific materials, meets the requirements of sectors with stringent safety and hygiene constraints (HACCP and FDA tanks). Extremely durable, the cubitainers can withstand the corrosion associated with the use of chemical and petroleum products (IBCs with UN and EX certification).

THE HIGH-PERFORMANCE EQUIPMENT IN AGITEC'S AG-IBC MIXER RANGE

Everything has been thought out to ensure that the AG-IBC range of mixers is high-performance and easy to use. The geared motor, variable speed drive and agitator form an assembly that provides rotation adapted to applications where miscible liquids need to be mixed, or where liquid/solid mixtures need to be put and/or kept in suspension. This type of motor is also suitable for the homogenisation process.

AN ASYNCHRONOUS GEARED MOTOR FOR AG-IBC stirrers

An asynchronous geared motor drives the agitator. This type of equipment offers refined, reliable speed transmission. Depending on your needs, we adapt the size of the motor to the constraints generated by the product. Built in Europe, the robustness of our drives is perfectly matched to the power ratings of the three sizes available in our range. These sizes allow you to select the most efficient solution for your particular needs.Thanks to their simple design, they require very little maintenance (few wearing parts). This reduces maintenance costs. The installed unit has a service life of around 50,000 hours.

A VARIABLE SPEED DRIVE TO MODULATE THE SPEED OF ROTATION OF THE MOVING PART

Being able to adapt the mixing effect perfectly to a process requirement very often results in significant savings in production time. For example, resuspending a decanted liquid often means using the full power of the agitator for a limited period of time. Once the liquids have been resuspended, the mixture needs to be mixed at a lower speed to keep it homogeneous. The use of a variable speed drive means that less electrical power is consumed, with greater efficiency and flexibility.The frequency inverter option allows you to modulate the speed of rotation of the mobile whatever the application.

AGITATORS AND PROPELLERS DESIGNED FOR IBC TANKS

Our R&D engineers have used digital fluid mechanics modelling to design a latest-generation folding propeller. Its specific design is perfectly adapted to the shape of the IBC. Its hydraulic performance is optimal. Its speed of rotation allows it to be deployed to obtain the desired mixing of the liquid throughout the tank. The agitator shaft has been sized to match the depth of standard IBCs. The diameter of the propeller is also specific to the characteristics of IBC containers.Storage feet enable the agitator to be kept on the floor without having to be placed on a container. The agitator support frame is fitted with openings for forklift forks. The optional lifting ring positioned at the centre of gravity allows the unit to be handled using a hoist or any other lifting system.

WHY USE STIRRERS FROM THE AG-IBC RANGE?

AGITEC, manufacturer of industrial mixers/agitators for over 30 years, innovates to support its customers' business. These innovations are often directly related to their needs, and it is thanks to a long-established relationship of trust that AGITEC is called upon to meet specific requirements in the field of agitation.

This new range has been launched to enhance a multi-sector product range in its entirety. It combines robustness, flexibility, efficiency and competitiveness for all types of mixing.

WHAT TYPES OF LIQUID AND WHAT VISCOSITY CAN BE STIRRED?

The agitators we have designed for IBCs can be used to mix a wide range of low- and medium-viscosity liquids. Depending on the application requiring a mixer, the liquids involved may be water-, oil-, chemical- or petroleum-based, or mixtures of miscible liquids for the food or pharmaceutical industries, for example.This type of mobile can withstand considerable viscosity, with mixtures of up to 8,000 centipoises. For example, enamels at the bottom of enamelling lines can be kept homogeneous in this type of container.

WHAT TYPES OF MIXTURES CAN AG-IBC STIRRERS BE USED FOR?

The AG-IBC range of stirrers is perfectly suited to mixing miscible liquids. The folding propeller and the speed of rotation produced by the geared motor/variable speed drive ensure perfect homogenisation at the end of the mixing process. The 3 blades of the propeller unfold once the mobile is in place in the tank and rotation starts, thanks to the lift of the liquid on the surface of the propeller blades.This type of mobile is also particularly suitable for suspending liquid/solid mixtures and keeping them in suspension or any other product that tends to settle. During a suspension operation, the purpose of the rotor is to obtain the best possible stability for the mixture obtained. During suspension, the purpose of the agitator is to ensure perfect homogenisation of the solid particles in the liquid phase.

Naturally, AG-IBC solutions are ideal for homogenising the various mixtures. To a lesser extent, the mixers in the AG-IBC range are also suitable for dispersion, dissolution and dilution processes. Talk to us about your project. We'll find the best solution for your application.

WHAT APPLICATIONS CAN AG-IBC MOBILE SHAKERS BE USED FOR?

The applications requiring agitation are as numerous as they are varied. In the food industry, for example, agitators are used to mix beverages with or without suspended matter (fruit juices with or without pulp). The materials used are designed to minimise the risk of contamination in this sector, where hygiene and safety standards are a prerequisite.There are also numerous standards in the cosmetics sector for which AGITEC offers a range of totally safe and reliable solutions. The products in the AG-ICB range are among them. In this field, our products respond favourably to the ever-growing needs of consumers in terms of requirements and innovations.

The AG-IBC range is also designed for the chemical, petrochemical and water treatment industries. While water treatment processes are subject to less stringent health and safety constraints, the requirements of the chemical and petrochemical industries can go as far as ATEX standards for applications in explosive atmospheres.

SOME OPTIONS AVAILABLE FOR IMPROVED AGITATION IN IBC TANKS

To meet all special requirements, we offer several options :

• Variable speed drive

The variable speed drives are equipped with a start-up switch and a potentiometer for speed variation, as well as a digital display.

• Handling ring

Handling rings allow the AG-IBCs to be lifted by hoist systems in complete safety.

• IBC presence sensor

These sensors detect the presence of the IBC to authorise the start-up of the agitator (option only available if the drive option is selected).

• Power cable

Three-phase cables fitted with HYPRA-type plugs are available in several lengths (from 10 to 20 metres).

• Storage feet

The feet are fitted to the AG-IBC chassis. They enable the agitator to be placed on the floor without risk of damage.

• Exotic material design

It is sometimes necessary to use top-of-the-range stainless steel to resist chemical attack. It is then possible, on request, to provide a specific material adapted to the mixed product, such as Uranus, Hastelloy, Inconel, etc.

Other options can be studied on request, for example, for ATEX applications in zone 1 or 2 T4.