Company : Quality

For 25 years, AGITEC® has undertaken to meet your explicit and implicit requirements, regardless of your sphere of activity.

Our quality approach consists of a participative continuous improvement process involving everyone in the company and all key sectors (design, manufacturing, traceability, FAT, services, after-sales service, etc) .

Traceability: We make it a point of honour to comply fully with traceability in the design of our stirrers.

- Material tracking

- Order tracking ERP

- Pre- and post-manufacturing technical quality control conducted internally by our technicians

FAT (factory acknowledgement tests) Static : Documentary control in close connection with the inspected agitator (manuals, as-built drawings, material certificate, welding book, welders' qualifications, etc.).

This includes a complete check of the conformity of the components delivered, in close relation to a customer order, as well as validation of the correct design of the agitator before shipment.

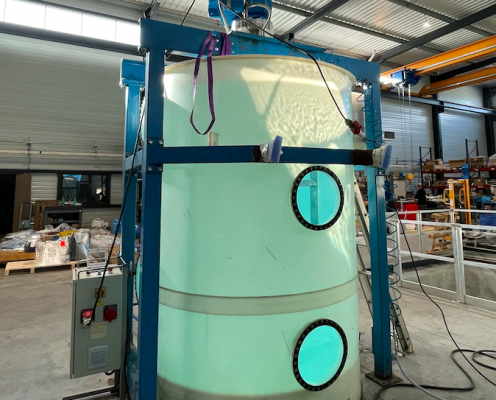

FAT (factory acknowledgement tests) Dynamic : Static FATs can be supplemented by full-scale tests on one of our test containers (from 100L to 40m³).

Dynamic FATs simulate the operation of the agitator under real conditions. That is, situations where the agitator has to adapt to variations in load or speed.

Service to assemble and help start up the stirrer(s)

To ensure the efficiency and quality of AGITEC® stirrers is maintained, a technical and human team is sent to help your company.

After-Sales: A team of qualified fast-response technicians to sort your preventive and remedial maintenance issues.

Guaranteed by the manufacturer for 2 years from the date of shipping.

Our quality approach consists of a participative continuous improvement process involving everyone in the company and all key sectors (design, manufacturing, traceability, FAT, services, after-sales service, etc) .

Traceability: We make it a point of honour to comply fully with traceability in the design of our stirrers.

- Material tracking

- Order tracking ERP

- Pre- and post-manufacturing technical quality control conducted internally by our technicians

FAT (factory acknowledgement tests) Static : Documentary control in close connection with the inspected agitator (manuals, as-built drawings, material certificate, welding book, welders' qualifications, etc.).

This includes a complete check of the conformity of the components delivered, in close relation to a customer order, as well as validation of the correct design of the agitator before shipment.

FAT (factory acknowledgement tests) Dynamic : Static FATs can be supplemented by full-scale tests on one of our test containers (from 100L to 40m³).

Dynamic FATs simulate the operation of the agitator under real conditions. That is, situations where the agitator has to adapt to variations in load or speed.

Service to assemble and help start up the stirrer(s)

To ensure the efficiency and quality of AGITEC® stirrers is maintained, a technical and human team is sent to help your company.

After-Sales: A team of qualified fast-response technicians to sort your preventive and remedial maintenance issues.

Guaranteed by the manufacturer for 2 years from the date of shipping.

AGITEC®: FRENCH MANUFACTURER OF STIRRERS ...

News

From full-scale testing to worldwide shipping

AGITEC makes every effort to ensure customer satisfaction.

New optimised mobiles for industrial mixers reduce energy consumption

New optimised mobiles for industrial mixers reduce energy consumption.

Installation of 2 stirrers aboard a cruise ship

Leroux et Lotz Technologies, a company specialising in environmental r...