Applications > Dissolution

What is dissolution?

Dissolution is the physico-chemical process by which a solute is incorporated in a solvent (we say the solute is dissolved) and forms a homogenous mixture called a solution. Formally, dissolution is defined as mixing of two phases with formation of a new homogenous phase.

Dissolution is the physico-chemical process by which a solid, liquid or gaseous substance (known as a solute) is brought into contact with a liquid or incorporated into a solvent where it is dissolved to form a homogeneous mixture called a solution.

Homogenisation by dissolution is a process which finds many applications in the industrial world, in sectors such as chemistry, petrochemistry, pharmacy, food processing or cosmetics.

Homogenisation by dissolution is a process that has many applications in the industrial world, particularly in the chemical, petrochemical, cosmetic, food and pharmaceutical laboratories.

What are the stirring techniques to obtain a dissolution?

To achieve homogeneous solutions, two agitating techniques will mainly use two types of equipment:

- magnetic stirrers equipped with turbines, propellers or anchors depending on the application concerned and the qualities of the solute used (viscosity, fibrous aspect, low or high miscibility, etc.).

In the dissolution process, the movement created by the agitator has a dual role: it creates dispersion from the physical point of view and absorption from the chemical point of view.

It is the technique most often used for solid/liquid mixtures, where it ensures faster dispersion, homogenisation and dissolution.

- static mixers which, thanks to the different shapes of the elements that make them up, make it possible to respond to many industrial applications. For example, helical elements that ensure the homogenisation of products by the turbulence created, or alternating Cross type elements that are more suitable for mixing high viscosity fluids.

What type of equipment should I choose for dissolving?

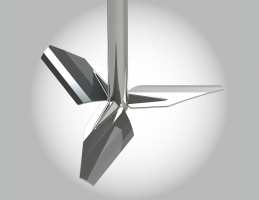

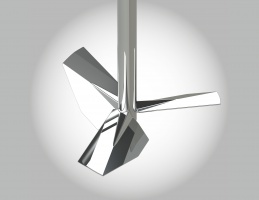

Depending on the specific needs of each application, a wide range of equipment (propellers and turbines) is available to obtain a perfect dissolution and is adaptable to both agitators and static mixers. Thanks to their small size, their stirring shaft allows the raw materials to be easily incorporated into the tank or container.

AGITEC's AX3 propeller is the preferred model when complex dissolving is required. The AX4 propeller may be preferred for the preparation of a device containing fibrous solids in the food industry for example.

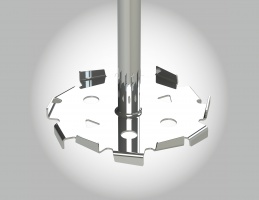

In our range of agitators, the dispersion impellers, thanks to their high peripheral speed, create a vacuum which centrifuges the liquids and solids sucked in and propels them through the teeth at the periphery of the disc.

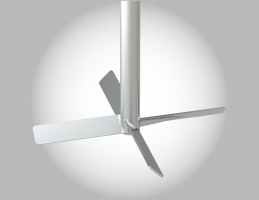

The TA4, TA3 and TA2 turbines have a double radial and axial effect. They can also be used for dissolving applications in industry. Our teams are at your service to provide you with all the necessary information concerning our stirring equipment.