Applications > Liquid/liquid dispersion

Liquid/liquid dispersion is a mixing process by stirring different miscible liquids of different viscosities in order to obtain their homogenisation.

In contrast to emulsion, which is a mixture of non-miscible liquids for which a permanent stability is sought, dispersion allows for ephemeral contact between the phases, with the aim of carrying out a material transfer as is the case for example in an extraction or during a chemical reaction.

The dispersion of one liquid in another in the form of droplets is a very common operation in all material processing industries, such as the chemical or petrochemical industry, cosmetics, pharmaceuticals or food processing, for whose applications it represents a key stage in the development of products, and therefore requires particular mastery of the process.

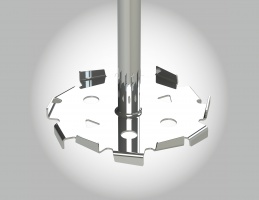

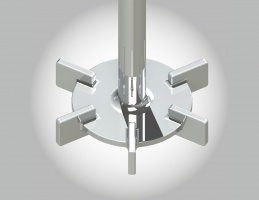

The liquid/liquid dispersion is carried out in tanks using agitators (stirrers).

Depending on the nature of the liquids or products used, the agitators are equipped with special propellers or turbines which ensure mixing with an optimal result, depending on the viscosity of the liquid, the presence of fibres or the sensitivity of the product to shear.