Applications > Gas/liquid dispersion

Gas/liquid dispersion is an efficient process that defines the incorporation of a gas in the form of small bubbles into a liquid, with the aim of obtaining chemical, biochemical and/or thermal reactions.

This operation involves different technical phases, with a number of parameters to be taken into account, such as the shear action, control of the shape and size of the incorporated gas bubbles, the speed of rotation of the agitator and the duration of the agitation or the viscosity level of the continuous phase.

Gas/liquid dispersion systems are suitable for a wide range of industrial applications where material transfer or chemical reaction between phases is required. This is the case in the chemical and petrochemical industry, pharmaceuticals, cosmetics and food processing (where gas bubbles can also be used to neutralise bacteria).

As the efficiency of the operation allowing the contact of a gas with a liquid strongly depends on the quality of the interface between phases and on the exchange area created, the use of the agitated tank proves to be the best solution in most dispersion applications, in the presence or not of solid particles.

In an agitated tank, the gas is therefore dispersed as bubbles within the liquid, by means of an agitator which will adopt a double role: firstly, to circulate the liquid and the gas, and secondly, to generate and control the dispersion of the gas.

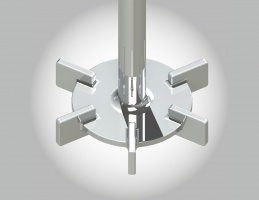

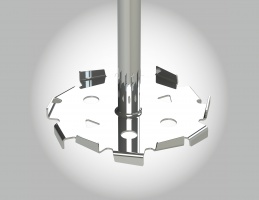

The use of specific turbines to equip magnetic stirrers, such as dispersion turbines with toothed discs, vertical blade discs (Rushton type) or toothed blade discs (Disgaz type), is decisive in order to maximise the length of the gas trajectory and its residence time in the tank.

In addition, these types of turbines optimise the efficiency of dispersion operations when the gas/liquid system is very coalescent, in the case of high transfer performance or when the process duration must be as short as possible.