Applications > Gas absorption

Absorption by agitation is possible from a liquid, solid and gaseous phase. This process is widely used for gas purification. The objective of the operation is to transfer a low concentration of a compound from a gas phase to the liquid phase. Absorption is therefore a phenomenon whereby a product in gaseous state dissolves into a liquid in the solvent.

Widely used for gas purification, the absorption of a gas by a liquid is a process that allows the mass transfer of a compound from the gas phase to the liquid phase. The physical dissolution of the compound into its liquid phase is carried out in several stages by a stirrer (or static mixer) equipped with a turbine or propeller.

In a tank, in the first step, the compound in the gas phase is diffused to the surface of the liquid. Then the stirrer will produce condensation/dissolution of the compound in the liquid phase. The last step is where the absorbed compound is dissolved and diffused into the liquid material, the solute is thus obtained.

The speed of absorption is favoured by the increase in the level of turbulence of the gas, allowing its presence in contact with the liquid to be rapidly renewed, and vice versa. Thus, the increase in the contact surface between gas and liquid will lead to a faster dissolution of the compound from the gas phase to the liquid phase.

It should be noted that, in the case of gas absorption with chemical reaction, the faster the chemical reaction takes place, the faster the transfer process will be accelerated.

Note that the transfer process is accelerated in the case of gas absorption with chemical reaction compared to absorption without chemical reaction.

Gas absorption is used in the field of purification by allowing the transfer of pollutants from the gas phase to the liquid phase.

It meets the regulatory requirements for the release of gases into the environment.

There are many applications in the treatment of odours (purification plants, rendering workshops, etc.) and solvents in the petrochemical industry,

the ink and paint industry, pharmaceuticals or biotechnologies.

Gas absorption is used in the field of purification by allowing the transfer of pollutants from the gas phase to the liquid phase.

It meets the regulatory requirements for the release of gases into the environment.

There are numerous applications in the treatment of odours (wastewater treatment plants, rendering plants, etc.) and solvents in the petrochemical, ink and paint, pharmaceutical and biotechnology industries.

Gas absorption also allows the simultaneous treatment of dust and gaseous pollutants.

Moreover, physical absorption (without chemical reaction) is a non-destructive technique which makes it possible, thanks to the regeneration of the liquid, to recycle the polluting species in the process, thus offering both technical and economic interest.

TURBINES

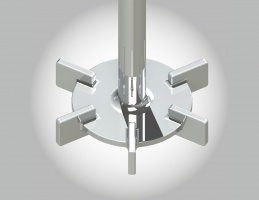

With a large number of blades (6 blades) the AGITEC® disgass and Rushton type turbines are perfectly suited for this type of mixing where the gas phase is absorbed by the liquid phase. The self-aspirating turbine is also designed for gas absorption. The centrifugal effect created by a system of openings on the tubular shaft allows the gas to be sucked in.

Widely used for gas purification, the absorption of a gas by a liquid is a process that allows the mass transfer of a compound from the gas phase to the liquid phase. The physical dissolution of the compound into its liquid phase is carried out in several stages by a stirrer (or static mixer) equipped with a turbine or propeller.

In a tank, in the first step, the compound in the gas phase is diffused to the surface of the liquid. Then the stirrer will produce condensation/dissolution of the compound in the liquid phase. The last step is where the absorbed compound is dissolved and diffused into the liquid material, the solute is thus obtained.

The speed of absorption is favoured by the increase in the level of turbulence of the gas, allowing its presence in contact with the liquid to be rapidly renewed, and vice versa. Thus, the increase in the contact surface between gas and liquid will lead to a faster dissolution of the compound from the gas phase to the liquid phase.

It should be noted that, in the case of gas absorption with chemical reaction, the faster the chemical reaction takes place, the faster the transfer process will be accelerated.

Note that the transfer process is accelerated in the case of gas absorption with chemical reaction compared to absorption without chemical reaction.

Gas absorption is used in the field of purification by allowing the transfer of pollutants from the gas phase to the liquid phase.

It meets the regulatory requirements for the release of gases into the environment.

There are many applications in the treatment of odours (purification plants, rendering workshops, etc.) and solvents in the petrochemical industry,

the ink and paint industry, pharmaceuticals or biotechnologies.

Gas absorption is used in the field of purification by allowing the transfer of pollutants from the gas phase to the liquid phase.

It meets the regulatory requirements for the release of gases into the environment.

There are numerous applications in the treatment of odours (wastewater treatment plants, rendering plants, etc.) and solvents in the petrochemical, ink and paint, pharmaceutical and biotechnology industries.

Gas absorption also allows the simultaneous treatment of dust and gaseous pollutants.

Moreover, physical absorption (without chemical reaction) is a non-destructive technique which makes it possible, thanks to the regeneration of the liquid, to recycle the polluting species in the process, thus offering both technical and economic interest.

TYPE OF EQUIPMENT ADAPTED TO THE GAS ABSORPTION APPLICATION :

TURBINES

With a large number of blades (6 blades) the AGITEC® disgass and Rushton type turbines are perfectly suited for this type of mixing where the gas phase is absorbed by the liquid phase. The self-aspirating turbine is also designed for gas absorption. The centrifugal effect created by a system of openings on the tubular shaft allows the gas to be sucked in.