Applications > Dilution

The purpose of the dilution process is to reduce the concentration of a solution.

Dilution is obtained either by adding a quantity of solvent to the initial solution, or by removing part of it and adding more solvent to keep the same volume as the original solution.

The prerequisite is that the diluted product is soluble in the liquid being used.

Dilution is defined by a rate: thus, a 50% dilution means that the concentration of the solution is divided by 2.

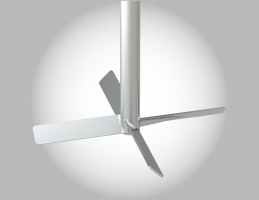

Dilution is carried out in a tank with a magnetically driven agitator equipped with a turbine, anchor or propeller. This process is frequently used for the dilution or mixing of food products, easily miscible liquids or powders in the food industry, fine chemicals or pharmaceuticals.

Depending on the case, the magnetic stirrer must ensure low turbulence for products or liquids of similar density and/or viscosity, whereas a higher level of stirring is required otherwise, to ensure a good efficiency of the dilution process.