Applications > disintegration

What is disintegration?

Disintegration (also known as deaggregation or deagglomeration) is a process that allows a solid to be disaggregated by the pressure exerted by a moving liquid. A magnetic stirrer or a static mixer creates this movement, whose action will lead to the complete dissolution of the solid in the solvent, until a homogeneous mixture called solution is formed.

When the solid whose properties have been modified has reached the end of its dissolution phase (it is then called a solute), the solution obtained is said to be saturated.

What are the industrial applications for chipping?

Spalling is a process widely used in the food, pharmaceutical and cosmetics industries, particularly for the manufacture of silica-based products, such as toothpaste, for example.

The disintegration is in fact one of the stages of a more complex preparation. It can take place after the preparation, in cosmetics, of silica (obtained for example by reaction of silicate and an acidifying agent). It can also be followed by the suspension of other particles.

In the food industry, disintegration is used, among other things, to process various seeds to obtain oil.

What type of equipment is used for slitting in the industry?

The disintegration of many solids can be achieved by means of a stirrer which can mix the particles in the liquid medium with sufficient speed. It should be noted that the sealing of the shaft passage is achieved by means of a mechanical seal system.

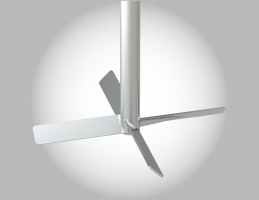

AGITEC's TA4, TA3, TA2 turbine in blowing flow mode drives the initial surface preparation downwards in the tank by creating a vortex that is conducive to breaking up. The slim blade shape of AGITEC's AX3 propeller also allows for slagging processes due to its very high shear at maximum rotation speed.