Applications > Mixing immiscible liquids

Unlike the mixing of miscible liquids, which results in a homogeneous solution and therefore in the end in a single phase, the process of mixing immiscible (or non-miscible) products by stirring will consist of the dispersion of one of the phases in the other to create a mass transfer in order to obtain a solution that is as homogeneous as possible.

In chemical terms, the solution is an emulsion, dispersion or mixture.

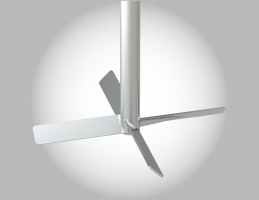

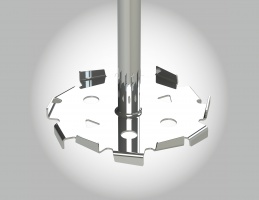

The process of mixing immiscible liquids is carried out in a tank (or other tank type container) using a stirrer equipped with moving parts such as turbines or propellers. The choice of the agitator and its equipment is decisive in the case of the mixing of immiscible products for the proper conduct of the operation.

In fact, where a conventional agitator will give satisfactory results to obtain a homogeneous solution with miscible liquids or liquids of similar viscosity, its use when the differences in miscibility between two liquids are significant will tend to stir the products more than to actually mix them.

The use of stirrer turbines is often the best solution to achieve uniform mixing from immiscible liquids or liquids with very different viscosities. By generating high turbulence and shear during agitation, the turbine (and in particular the rotor/stator type) will enable the most homogeneous solution to be obtained in the shortest possible time, while at the same time controlling the energy expenditure required to achieve this.

These specific operations for mixing immiscible liquids find numerous applications in the pharmaceutical and biotechnology sectors, but also in the food and cosmetics industries.