Markets : Chemicals/Petrochemicals

80% OF ALL MANUFACTURED STIRRERS ARE INTENDED TO BE MOUNTED ON REACTORS, AT THE HEART OF PRODUCTION THAT REQUIRES HIGH RELIABILITY DURING LONG-TERM USE WITHOUT SHUTDOWNS.

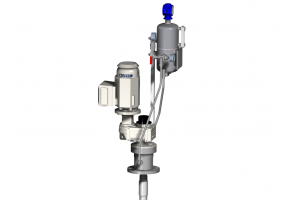

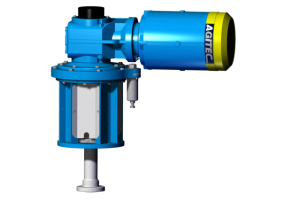

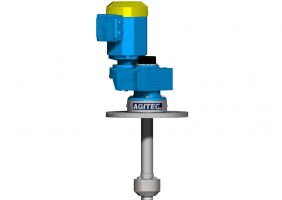

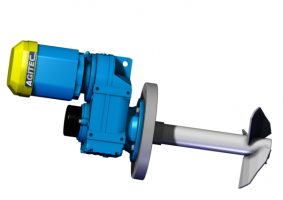

STIRRER WITH MECHANICAL DRIVE FOR VARIOUS SILICA-BASED APPLICATIONS

To respond to significant environmental restrictions, AGITEC® manufactures bespoke stirrers with a mechanical drive and sophisticated sealing for silica-based manufacturing (toothpaste, tyres, rubber, etc). The machines are quick and easy to maintain. For these applications, AGITEC® has partnered up with major manufacturers of motors, gearboxes and mechanical seals.

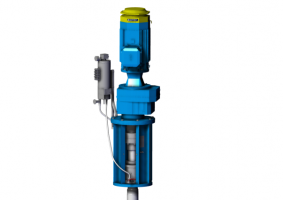

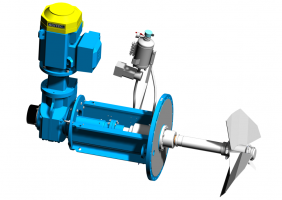

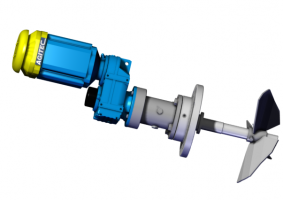

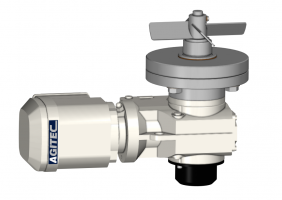

MAGNETIC STIRRER IN EXPLOSIVE ATMOSPHERES

Hydrogenation, the most difficult chemical process, is characterized by high pressure (up to 250 bars) and high temperatures (up to 400°), which can be extremely hazardous if there is a hydrogen leak.

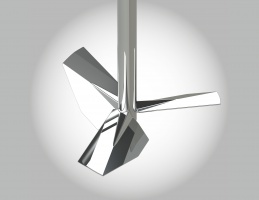

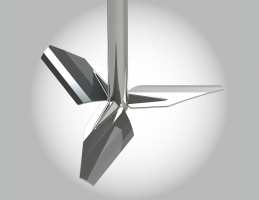

AGITEC® manages the demands of explosive atmospheres by complying with ATEX standards and adding restrictions in terms of cleanliness and ease of cleaning. AGITEC® supplies magnetic stirrers that can cope with these difficult conditions, and in addition have a mechanical seal. The machines are ultra-clean, with no retention pockets, and have polished surfaces.

Example: AGITEC® is involved in creating PVC with ultrapolishing to prevent rubble forming around the rotating parts during a stripping process.

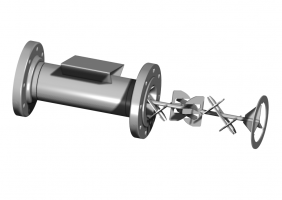

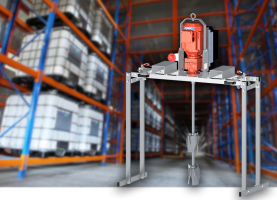

IN-LINE POLYMER INCORPORATOR

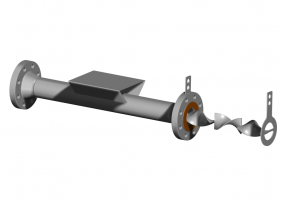

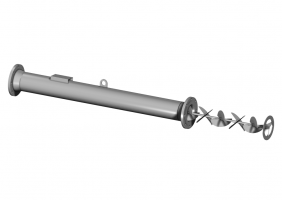

In collaboration with a French-Canadian college, AGITEC® has developed a dynamic in-line mixer that can be used to incorporate polymers in liquid bitumen for new self-draining highway surfacing.

PETROCHEMICALS

AGITEC® is involved in homogenization of oil stocks, refined products and aviation kerosene.

When chemicals and farming come together, AGITEC® is a player in the “green fuel” (diester ethanol) process.

For Chemical and Petrochimicals applications, AGITEC® offers this equipment

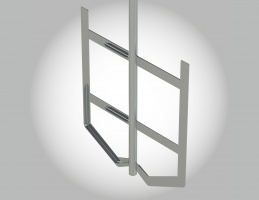

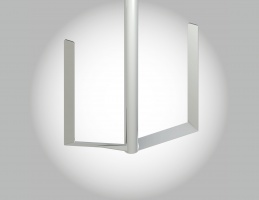

STIRRER WITH MECHANICAL DRIVE FOR VARIOUS SILICA-BASED APPLICATIONS

To respond to significant environmental restrictions, AGITEC® manufactures bespoke stirrers with a mechanical drive and sophisticated sealing for silica-based manufacturing (toothpaste, tyres, rubber, etc). The machines are quick and easy to maintain. For these applications, AGITEC® has partnered up with major manufacturers of motors, gearboxes and mechanical seals.

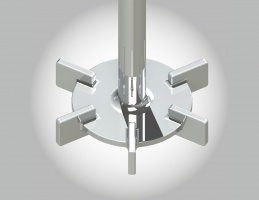

MAGNETIC STIRRER IN EXPLOSIVE ATMOSPHERES

Hydrogenation, the most difficult chemical process, is characterized by high pressure (up to 250 bars) and high temperatures (up to 400°), which can be extremely hazardous if there is a hydrogen leak.

AGITEC® manages the demands of explosive atmospheres by complying with ATEX standards and adding restrictions in terms of cleanliness and ease of cleaning. AGITEC® supplies magnetic stirrers that can cope with these difficult conditions, and in addition have a mechanical seal. The machines are ultra-clean, with no retention pockets, and have polished surfaces.

Example: AGITEC® is involved in creating PVC with ultrapolishing to prevent rubble forming around the rotating parts during a stripping process.

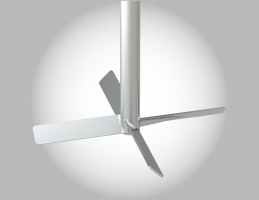

IN-LINE POLYMER INCORPORATOR

In collaboration with a French-Canadian college, AGITEC® has developed a dynamic in-line mixer that can be used to incorporate polymers in liquid bitumen for new self-draining highway surfacing.

PETROCHEMICALS

AGITEC® is involved in homogenization of oil stocks, refined products and aviation kerosene.

When chemicals and farming come together, AGITEC® is a player in the “green fuel” (diester ethanol) process.

For Chemical and Petrochimicals applications, AGITEC® offers this equipment

News

New investment in the industrial paint market

A reindustrialisation programme launched in 2021.

HORIZONTAL LATERAL EXTRACTION STIRRERS : a revolution for the oil industry

The AGITEC® range of side-extraction stirrers is a major step forward ...

Introducing a mega-disperser for the paint industry

A front cover and double page spread devoted to a major project for th...