Markets : Pharmaceuticals/Biotechnology

Pharmaceuticals and the veterinary sector have much in common, being characterized by major constraints concerning traceability and ease of cleaning. In addition they are subject to international standards, especially FDA (Food and Drug Administration) standards in the US for injectable products, vaccines, oral medicine and suppositories.

50% of machines manufactured and installed by AGITEC® for these applications are magnetic stirrers

EMULSION OF THE ACTIVE INGREDIENT:

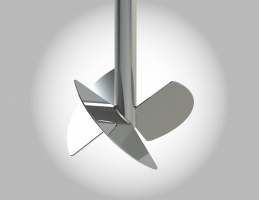

AGITEC® manufactures machines designed to emulsify the active ingredient in inert carriers (eg: glycerine for suppositories). Emulsion is a means to incorporate an active ingredient in these inert bases. When the product dissolves inside the human or animal, it will spread around the body. This emulsion application is also found in the manufacture of oral medicine.

FERMENTATION

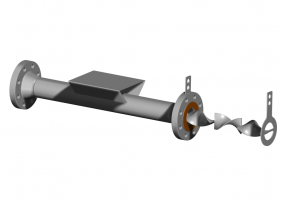

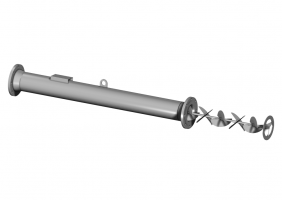

The principle of fermentation is amongst other things to develop bacteria in order to make vaccines. AGITEC® is working in collaboration with the main contractors to create an environment in which bacteria cultures can be grown. A stirrer is placed in each vessel so these microbes can develop.

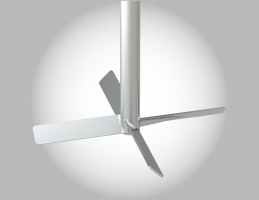

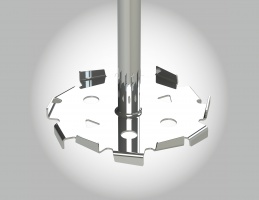

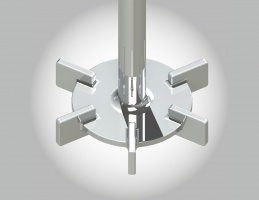

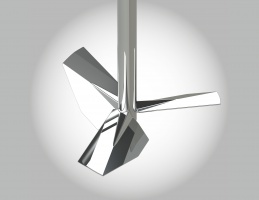

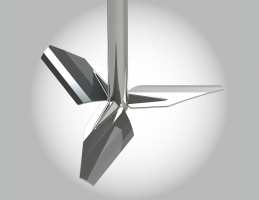

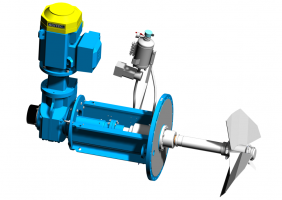

Depending on the type of fermentation - bacterial or cell culture - the type of stirring differs completely. For bacterial fermentation, AGITEC® is developing machines with strong dynamics to oxygenate the bacteria, whereas cell culture fermentation requires slow stirring to avoid destroying the cells that usually reproduce on micro-carriers (silica beads to which the cells become attached, that help them reproduce).

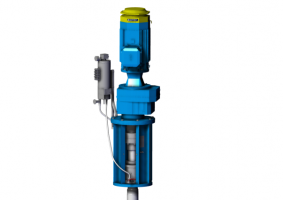

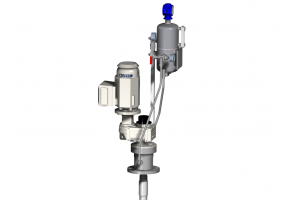

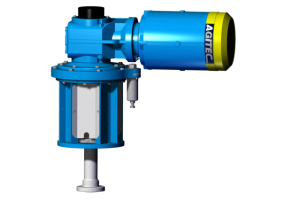

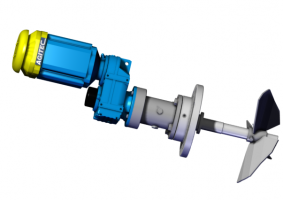

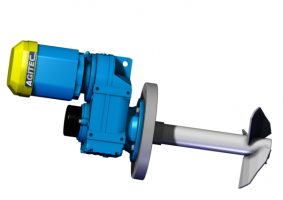

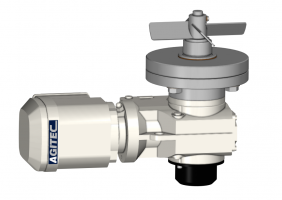

For pharmaceuticals and biotechnology applications, AGITEC® offers this equipment

50% of machines manufactured and installed by AGITEC® for these applications are magnetic stirrers

EMULSION OF THE ACTIVE INGREDIENT:

AGITEC® manufactures machines designed to emulsify the active ingredient in inert carriers (eg: glycerine for suppositories). Emulsion is a means to incorporate an active ingredient in these inert bases. When the product dissolves inside the human or animal, it will spread around the body. This emulsion application is also found in the manufacture of oral medicine.

FERMENTATION

The principle of fermentation is amongst other things to develop bacteria in order to make vaccines. AGITEC® is working in collaboration with the main contractors to create an environment in which bacteria cultures can be grown. A stirrer is placed in each vessel so these microbes can develop.

Depending on the type of fermentation - bacterial or cell culture - the type of stirring differs completely. For bacterial fermentation, AGITEC® is developing machines with strong dynamics to oxygenate the bacteria, whereas cell culture fermentation requires slow stirring to avoid destroying the cells that usually reproduce on micro-carriers (silica beads to which the cells become attached, that help them reproduce).

For pharmaceuticals and biotechnology applications, AGITEC® offers this equipment

News

From pre-industrialisation to mass production

AGITEC manufactures stirrers to meet the specific needs of chemists an...

Re-industrialisation of flavonoids production in Europe

The re-industrialisation of flavonoids has begun in Europe...