Markets : Cosmetics

Between the development of a cosmetic formula in the laboratory and the consumer, the industrial phase must meet the qualitative demand of the market. AGITEC® presents its range of industrial stirrers and mixers used in the manufacture of cosmetics: vessel-roof stirrer, lateral stirrer, vessel-bottom stirrer, static mixer, anchor, scraper, turbine, propeller.

The cosmetics sector has been growing steadily, from 3.6% to 5.5% per year since 2010 (source: L'Oréal study). This consistency is stimulated by the requirements of French and international consumers. New products and ranges, ambassadors of French know-how, are developed on a daily basis.

The cosmetics market adapts to needs:

- Consumers who are increasingly better informed and demanding the quality of the products used.

- Research and development of innovative formulas for new products

- An ever-increasing environmental constraint

AGITEC® presents products designed for these applications used in cosmetic industry processes: thermal transfer, suspension, liquid/fibrous solid mixture, miscible liquid mixture, suspension retention, homogenization, emulsion, dissolution, dilution, deltination, solid/liquid dispersion, liquid/liquid dispersion, gas/liquid dispersion.

To each device its characteristics and services, AGITEC® provides all useful information on the capacities of its products and the solutions of its production systems.

For Cosmetics applications, AGITEC® offers this equipment

The cosmetics sector has been growing steadily, from 3.6% to 5.5% per year since 2010 (source: L'Oréal study). This consistency is stimulated by the requirements of French and international consumers. New products and ranges, ambassadors of French know-how, are developed on a daily basis.

The cosmetics market adapts to needs:

- Consumers who are increasingly better informed and demanding the quality of the products used.

- Research and development of innovative formulas for new products

- An ever-increasing environmental constraint

AGITEC® presents products designed for these applications used in cosmetic industry processes: thermal transfer, suspension, liquid/fibrous solid mixture, miscible liquid mixture, suspension retention, homogenization, emulsion, dissolution, dilution, deltination, solid/liquid dispersion, liquid/liquid dispersion, gas/liquid dispersion.

To each device its characteristics and services, AGITEC® provides all useful information on the capacities of its products and the solutions of its production systems.

For Cosmetics applications, AGITEC® offers this equipment

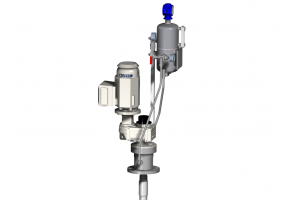

- Vessel-roof stirrer

AGITEC® has developed a range of industrial vessel-roof stirrer designed and adapted for the cosmetics industry:

AG-R Simple, single ewwxtension

AG-R Compact, compact extension

V-Ring seal stirrer / Lip seal / Deflector

AG-ContraRotative, with double agitation

AG-Potences, Agitation on Up and Down Stems

Stirrer for IBC containers

Clamp stirrer for tank edge

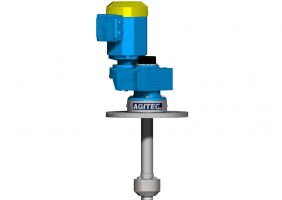

- Lateral stirrer

AGITEC® has also designed a compact AGL-R COMPACT lateral stirrer with a compact extension for mixing cosmetics. This agitator is suitable for small and medium size agitation

Vessel-bottom stirrer

These products are suitable for many applications in the cosmetics industry.

AGF-R COMPACT

AGF-R SIMPLE - Static mixers

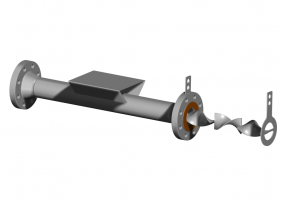

Static mixers allow the creation of turbulence which makes it possible to mix products.

MS-ELLIP

MS TOR

MS-HIGH SHEAR

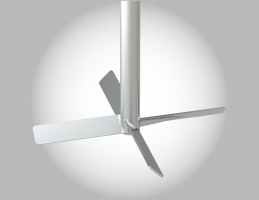

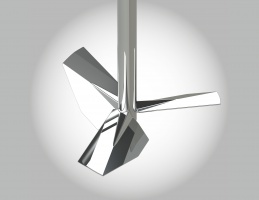

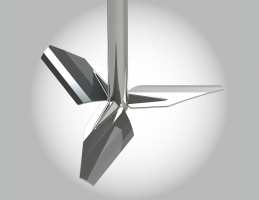

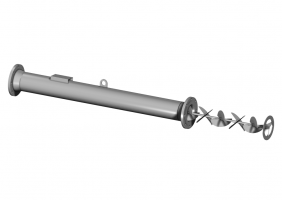

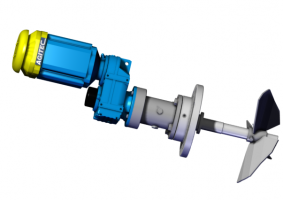

- Propellers

AGITEC® develops 4 types of propellers with extended characteristics: high hydraulic lift, speed, mixture of liquids containing fibres, high shear.

AX1

AX2

AX3

AX4

MARINE

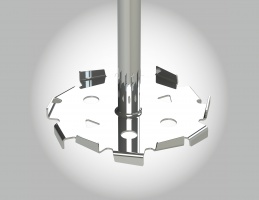

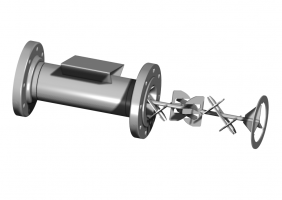

- Turbines

These dispersion equipments allow to obtain several centrifugal effects.

3PC, 6PC

TA4, TA3, TA2

TF2, TF3

Dispersion turbine

Mobile rotor/stator

- Anchor

Heat exchange, homogenization of high viscosity products, tangential or axial flow anchors allow homogeneous mixtures to be obtained.

Helical anchor

Scraper anchors

Tubular anchor

News

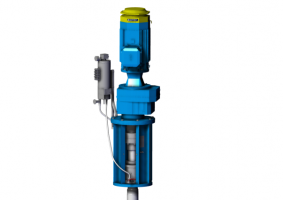

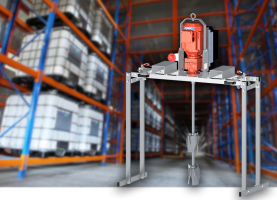

Luxury disperses with AGITEC

New range of ultra-clean dispersers developed by AGITEC.